Trout Scientific Illustration Beef Cow Scientific Illustration

Introduction to cultivated meat

What is cultivated meat?

Cultivated meat, also known equally cultured meat, is genuine animal meat (including seafood and organ meats) that is produced by cultivating animate being cells directly. This production method eliminates the need to raise and farm animals for food. Cultivated meat is made of the same cell types arranged in the aforementioned or like structure as fauna tissues, thus replicating the sensory and nutritional profiles of conventional meat.

Dutch scientist Marker Post unveiled the first cultivated meat burger on live television receiver in 2013. Two years afterward, the showtime four cultivated meat companies were founded. The industry has since grown to more than lx companies on half-dozen continents, backed by $450M+ in investments, each aiming to produce cultivated meat products. Dozens more companies accept formed to create technology solutions along the value chain.

Decades of accumulated knowledge in cell culture, stem prison cell biological science, tissue engineering science, fermentation, and chemical and bioprocess engineering preceded the field of cultivated meat. Hundreds of companies and academic laboratories worldwide are conducting research beyond these disciplines to institute a new paradigm for manufacturing article meat products at industrial scales.

How is cultivated meat made?

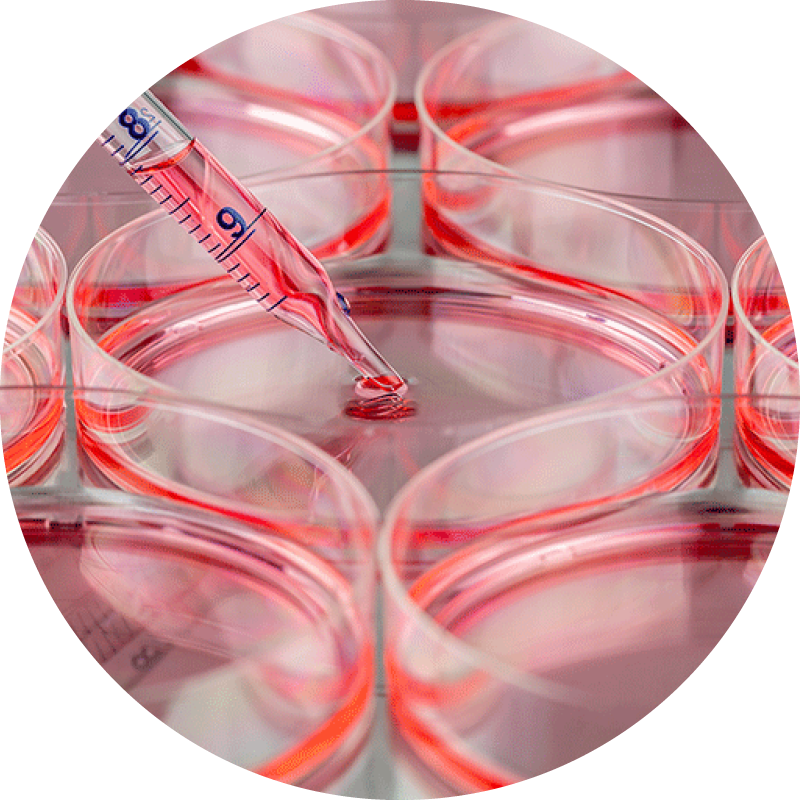

The manufacturing process begins with acquiring and banking stalk cells from an animal. These cells are then grown in bioreactors (known colloquially as cultivators) at loftier densities and volumes. Like to what happens inside an creature's body, the cells are fed an oxygen-rich cell culture medium made up of basic nutrients such equally amino acids, glucose, vitamins, and inorganic salts, and supplemented with proteins and other growth factors.

Changes in the medium composition, often in tandem with cues from a scaffolding structure, trigger immature cells to differentiate into the skeletal muscle, fat, and connective tissues that make up meat. The differentiated cells are then harvested, prepared, and packaged into final products. This process is expected to take between 2-8 weeks, depending on what kind of meat is being cultivated. Some companies are pursuing a like strategy to create milk and other dairy products.

What are the benefits of cultivated meat?

By nature of its more efficient production process, cultivated meat is expected to accept a variety of benefits over conventional creature agronomics. Prospective life cycle assessments indicate that cultivated meat will use significantly less country and water, emit fewer greenhouse gases, and reduce agriculture-related pollution and eutrophication.

According to a 2020 publication in Nature Food, commercial product is expected to occur entirely without antibiotics and is likely to result in fewer incidences of foodborne illnesses due to the lack of exposure risk from enteric pathogens.

Over the next few decades, cultivated meat and other alternative proteins are predicted to have significant marketplace share from the $ane.seven trillion conventional meat and seafood industry. This shift will mitigate agriculture-related deforestation, biodiversity loss, antibody resistance, zoonotic disease outbreaks, and industrialized animal slaughter.

When will cultivated meat get in to marketplace?

As of mid-2020, several leading cultivated meat companies are transitioning to pilot-scale facilities that will manufacture the outset moving ridge of commercialized products following regulatory approval. The Singapore Food Bureau approved the world's start cultivated meat product for sale in December 2020. Shortly thereafter, the 1880 eating place in Singapore marked the historic first commercial sale of the approved cultivated chicken bite produced by California-based Swallow Simply.

Further scaling product to significantly larger facilities than what currently exists will require solving an assortment of circuitous challenges. These challenges range beyond four key areas: cell lines, cell culture media, bioprocess design, and scaffolding.

Solving these challenges and propelling the cultivated meat industry into maturity will require an influx of funding from both the public and private sectors. New courses, enquiry centers, and preparation programs for scientists, every bit well every bit policy work and regulatory action will advance progress.

The field will also demand new companies, contributions from existing life science companies, and openness to collaboration from existing cultivated meat companies. Many new career opportunities will need to exist filled by talented scientists, businesspeople, and other contributors along the value chain.

Cell lines

Many dissimilar cell types tin can be used to cultivate meat. Farther inquiry is needed to make cell lines more accessible and to determine how the selection of a cell blazon and its properties influence the downstream process considerations.

The current country of cell lines

Many cell types can exist used to cultivate meat.

The starting inputs for cultivated meat are cells that can self-renew and differentiate, otherwise known as stalk cells. Stalk cells used for cultivated meat product can exist acquired or derived in several means. The nigh mutual method is taking a cell sample from a live animal. This can be done using minimally invasive methods.

Different types of stalk cells, such as skeletal muscle stem cells (i.e., myosatellite cells), adipogenic stem cells, or mesenchymal stem cells, tin be acquired in this manner. Stem cells can also exist obtained by taking a cell sample of specific organs to create other products. For example, cells from mammary glands can be used for milk production, and cells from livers for foie gras. In some cases, these cells may be caused by biopsying a recently slaughtered animal where the tissue is withal viable, which could be important for determining compliance to religious laws (e.thou., halal, kosher).

Stalk cells known as pluripotent stalk cells can be acquired from an early-phase embryo. Cells such as fibroblasts or peripheral blood mononuclear cells can exist reprogrammed into induced pluripotent stalk cells. Those source cells are obtained from methods such as a cheek swab or blood draw. In all cases, the acquired cells originate from good for you animals alongside extensive documentation that ensure the quality and traceability of the cells.

Deriving cell lines requires many resources.

Currently, the bulk of cultivated meat manufacturers work with well-characterized cell lines, which take the ability to continuously proliferate over time. Some producers may select primary cells, which past definition accept a finite life span. Currently, access to cell lines from species used for cultivated meat production is the major barrier for new research endeavors.

The cosmos of new prison cell lines can be both fourth dimension- and resource-intensive, often taking 6-18 months to derive and sufficiently characterize a unmarried line. In medical inquiry, the cosmos of large-scale cell line biorepositories is oftentimes nationally-sponsored, emphasizing their fundamental importance in advancing research. Similar government-backed projects are needed in cultivated meat.

Increasing access to cell lines is a priority for the manufacture.

To accelerate jail cell line availability, GFI is funding multiple research projects that create cell lines from species spanning livestock, poultry, and aquatic animals. GFI has also partnered with reagent provider Kerafast to depository financial institution and distribute cell lines submitted past researchers from around the world in academia and manufacture. B2B companies specializing in cell line creation and distribution are pursuing similar strategies.

Boosted efforts are needed to generate and characterize cell lines from more than species and different cell types, create protocols for prison cell isolation and culturing weather condition, and discover low-cost, animal-free cell culture medium formulations. Partnerships with conventional meat producers and aquaculture groups that often piece of work with creature cell lines may accelerate R&D in these areas.

Cell line challenges

Cell types have specific pros and cons.

As described previously, there are many cell types that can be used equally starting inputs for cultivated meat production. Notwithstanding, more inquiry is needed to determine which cells will exist best suited for large-scale manufacturing or the creation of specific product types. Intrinsic prison cell characteristics, such as suitability for suspension growth, doubling times, growth rates, metabolism, differentiation capacity, and genomic stability can vary between cell type and species.

These characteristics must be weighed aslope techno-economic models and bioprocess design considerations to inform cell line choice. However, this is challenging. Species used in cultivated meat production (particularly aquatic animals) are much less researched than humans, mice, or hamsters, which have been the mainstay of the biomedical and biopharmaceutical industries.

Technology cells tin inform research and development.

Cell technology tin accelerate the development of prison cell lines suitable for cultivated meat. Technology cell lines can dramatically meliorate the efficiency or productivity of the production procedure, or even influence stop product attributes such as nutrition.

Jail cell line engineering can accept place in the form of adaptation or genetic applied science. Adaptation involves the serial subculture of a cell line in varying weather along with selection over time. This procedure yields a cell line adapted to a new fix of conditions or exhibiting a new trait. Mutual forms of accommodation include adaptation to serum-free medium or suspension growth.

Genetic engineering entails permanent changes by either removing, rearranging, or introducing Dna. While some cultivated meat companies have stated they practice not plan to use genetic engineering, several others have filed patents describing various engineering approaches. Ultimately, the extent of genetic engineering and types of modifications incorporated into final products will be dependent on the regulatory approval procedure for engineered products, likewise equally consumer perceptions in different regions.

What comes adjacent for cell lines

Democratization of cell lines will open up new doors.

In the futurity, researchers will accept piece of cake access to many well-characterized cell lines housed in multiple biorepositories spread across the globe. To go there, more public funding is needed to attract experienced stem cell biologists who can use their knowledge and tools to the cultivated meat field. Researchers and companies akin should exist motivated and incentivized to eolith cell lines in public repositories to lower the burden of entry throughout the industry.

To assistance overcome challenges in cell line engineering, life science companies and contract research organizations that specialize in jail cell line evolution are needed. These companies can apply high-throughput techniques and automation technologies to improve prison cell line R&D and engineering efforts. Together, these efforts can support a more than robust inquiry ecosystem that will generate new findings, create new tools, reduce costs, and advance the footstep of commercialization.

Check out additional reading and resource

Discover papers, GFI resources, ongoing research projects, and research opportunities related to cell lines.

- Featured article

- GFI resources

- Current research

- Research opportunities

Featured article

Read "Coming together the needs of the cell-based meat industry" published in the Chemical Engineering Process magazine

GFI resource

Dig into open up-admission resource created by our experts.

Expanding access to cell lines

Lack of access to cell lines is a major bulwark to cultivated meat research. This initiative is increasing access and funding the development of new lines.

GFI-funded inquiry projects

Learn about ongoing inquiry by GFI grantees to accelerate cell line development for cultivated meat.

Research opportunities

Explore inquiry opportunities in cell lines from our Advancing Solutions for Culling Proteins database.

-

Cultivated

Incorporating omega-3s into cultivated seafood

Cultivated seafood volition demand to be supplemented with long-chain omega-iii polyunsaturated fatty acids to be nutritionally equivalent or superior to conventional seafood. However, how these compounds tin best be incorporated…

-

Cultivated

Co-cultured support cells for cultivated meat

Cultivated meat research focuses primarily on muscle fibers and fat cells. However, other cell types serve functions that are often under appreciated in their relevance to cultivated meat. Co-culture methods…

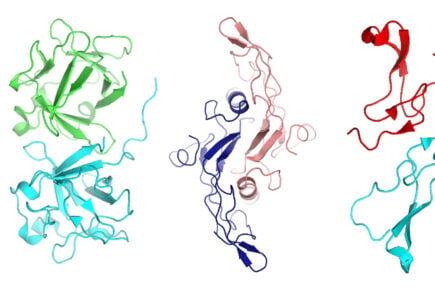

The prison cell culture media contains the nutrients and growth factors that cells need to abound outside of the body. Research on optimized formulations, animal-free components, and recycling technologies are needed to make cell civilization media significantly more affordable.

The current country of jail cell culture media

What's in jail cell civilization media?

The cell culture media is the nearly important technology underlying the about-term success of the cultivated meat manufacture. Cell culture media is equanimous of two groups of components tailored to a specific cell or species blazon.

The starting time grouping of components, called the basal media, provides essential nutrients. It typically consists of a buffered solution containing glucose, inorganic salts, h2o-soluble vitamins, and amino acids. The 2d is a group of specific added factors which permit the long-term maintenance, proliferation, or differentiation of cells. These added factors are frequently recombinant proteins, growth factors or hormones, and other ingredients such equally lipids and antioxidants.

Animal serum will not exist used in production.

While the basal media has persisted nearly unchanged since the 1950s, a transition away from other added factors originating from brute sources such as serum is nonetheless underway in many industries. The use of animal-derived components in cultivated meat product has prohibitive economic, food rubber, and ethical constraints. Many companies have already publicly stated they are using medium formulations that are entirely animal-free, with many others likely to have already achieved this milestone.

The commencement canonical cultivated meat production in Singapore was produced using fetal bovine serum (FBS), which is removed from the terminal product before consumption. The manufacturer Eat But has stated that the next moving ridge of time to come products would be manufactured using entirely plant-based ingredients, foregoing the employ of FBS.

Prison cell culture media challenges

Meaning cost reductions are possible without big technological leaps.

The largest claiming the cultivated meat manufacture faces is non simply foregoing animal components in the cell culture media but rather discovering how to practice and then affordably and how to optimize affordable formulations for maximized productivity.

Media cost reduction models accept projected achievable prices of less than $0.25 per liter using existing technologies. This would corporeality to upwards of a 99.nine% cost reduction versus media manufactured and sold to the biomedical and biopharmaceutical industries — a seemingly daunting task.

Still, considerable progress has already been made in achieving these dramatic cost reductions. For instance, a squad of researchers at Northwestern University demonstrated a popular stem jail cell medium formulation could be produced for 97% less versus its commercially-sold analogue.

Mosa Meat, a leading cultivated meat company in kingdom of the netherlands, appear in July of 2020 that they had reduced their medium costs past 88 fold. The XPRIZE Foundation is currently seeking teams that will exist awarded a $2M prize by developing an animal-free medium at the lowest toll.

Reducing costs of recombinant proteins is the largest toll reduction lever.

Multiple options for toll reduction are beingness pursued across the manufacture. The most urgent activity is to address the high costs of recombinant proteins and growth factors. While some B2B manufacturers are scaling the production of proteins and growth factors using microbes, fungi, or plants every bit expression systems, others are looking to replace these proteins and growth factors with constitute-based alternatives.

Costs tin can likewise be reduced by sourcing media components at nutrient or feed course, reducing the overhead and operational costs associated with producing pharmaceutical-grade components. This means that information technology is probable that much of the glucose and amino acids — which together make up the bulk of the cellular biomass — will originate from arable crops and readily-grown microbes.

Some cultivated meat companies have already struck partnerships with animal feed manufacturers to obtain these components at feed-course, allowing them to tap into mature supply chains.

Demand forecasts can help to predict industry needs.

Many existing media manufacturers have the capacity to contribute to the cultivated meat industry, merely data-driven projections of total volumes and demand forecasts for specific media components are needed to incentivize these manufacturers to mobilize the appropriate resource.

Challenges notwithstanding remain in identifying the sources of upstream raw materials that are best suited for each species and prison cell blazon used by cultivated meat manufacturers. Several methods can be used to reach desired performance results through formulation optimization. However, publicly-available information on cell-specific formulations volition be needed. These open data can be used for machine learning applications and to refine computationally-assisted algorithms for in silico experiments that save fourth dimension and costs.

Life science companies with high-throughput and microfluidic capabilities can also lend services for formulation discovery. Importantly, the choice and production of these raw materials will besides be influenced by how they fit into to-be-determined regulatory frameworks, their environmental sustainability footprints, and the social sustainability implications for the farmers and other workers along the value chain.

What's next for cell civilisation media?

Long-term optimizations volition contribute to further cost reduction and sustainability improvements.

There are many additional opportunities for toll reduction and optimized formulations that are probable to contribute to the commercial success of cultivated meat over longer time horizons. These include developing novel technologies for medium recycling, valorizing waste material streams or metabolites produced by cells, engineering growth factors with improved backdrop, and researching how cell culture media components influence the nutritional profiles of end products. Progress in each of these areas will require more public funding as well every bit co-developing solutions with participants from academia, the life scientific discipline industry, and the cultivated meat industry.

Check out additional reading and resource

Discover papers, GFI resources, ongoing research projects, and research opportunities related to prison cell culture media.

- GFI resources

- Current inquiry

- Inquiry opportunities

GFI resources

Dig into open-access resources created by our experts.

GFI-funded research projects

Acquire nigh ongoing research past GFI grantees to advance advances in cell culture media.

Inquiry opportunities

Explore research opportunities in cell culture media from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

B2B media evolution visitor

The cultivated meat industry needs defended suppliers of depression-cost, food-grade cell culture media to reduce cultivated meat production costs. Close collaboration between the customer and supplier will be required in…

-

Cultivated

Incorporating omega-3s into cultivated seafood

Cultivated seafood will need to be supplemented with long-chain omega-3 polyunsaturated fatty acids to be nutritionally equivalent or superior to conventional seafood. All the same, how these compounds can best be incorporated…

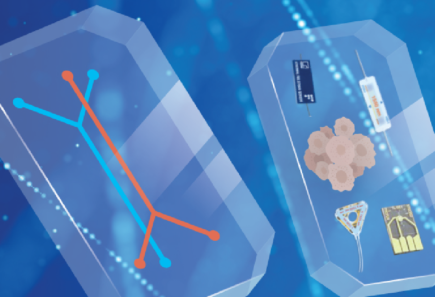

Bioprocess design

The bioprocess blueprint holds the key to unlocking large-calibration production of cultivated meat. Additional enquiry is needed to determine the best-suited bioreactors for different cell types and products as well as how future facilities will be operated.

The current state of bioprocess design

Bioreactors permit large-scale jail cell tillage.

The most important aspect of the bioprocess pattern is the bioreactor. Bioreactors (known colloquially every bit cultivators) provide the housing and control the conditions that enable cells to grow. For case, bioreactors command the temperature, oxygen levels, and commitment of cell culture media.

They too enable monitoring of other of import parameters such equally metabolite levels, pH, and biomass accumulation. Different types of bioreactors have long-continuing histories in other industries that rely on animal cell civilisation. Current models are being used by cultivated meat manufacturers at this fourth dimension.

Innovations in bioreactor technology represent a large whitespace opportunity.

However, these current models of bioreactors are not necessarily optimized for cultivated meat production. This is because the bioreactor and overall bioprocess pattern are influenced by the selection of cell type and its properties (eastward.grand., anchorage dependence), the cell civilisation media composition, and the overall goals of the process.

While some aspects of proliferation and differentiation overlap with other industries, cultivated meat manufacturers must optimize to perform those operations efficiently at very large scales and very low costs throughout the process. This suggests that novel bioreactor designs and modes of performance may be pursued by cultivated meat manufacturers and B2B suppliers.

Funding and consortia focused on bioreactors have begun to mobilize.

Discovering what aspects of existing bioreactors may be changed or how new bioreactors may exist designed is an area of active enquiry. In industry, several B2B companies aim to develop novel bioreactors for cultivated meat manufacturers, including those that operate continuously. Big life science companies such as Merck KGaA, Darmstadt, Deutschland, accept sponsored inquiry grants for novel designs.

Multiple companies and other stakeholders have formed the Cultivated Meat Modeling Consortium, which aims to employ computational modeling techniques to answer questions related to bioprocess design that may otherwise be overly resources- or fourth dimension-intensive to pursue. Additional collaborations betwixt cultivated meat manufacturers and life science companies or researchers experienced in fermentation and bioprocess calibration-up may fare well in accelerating R&D in this area.

Bioprocess pattern challenges

Airplane pilot-scale facilities correspond the kickoff major scale-up progress.

Scaling up a bioprocess generally takes place in iii separate phases: lab-scale, pilot-scale, and demonstration or commercial scale. Every bit cultivated meat companies move into their pilot-scale facilities, they volition face up the claiming of designing efficient, fit-for-purpose bioprocesses that tin can either scale upwards to sizes that dwarf existing fauna cell culture facilities or scale out using processes and facility designs that are portable.

Insights into potential bottlenecks for these facilities tin can be gained by funding open-access techno-economic models and facility blueprints with an eye toward both regulatory and sustainability considerations. Once achieved, a menu of flexible financing options for future facilities will exist needed. The formation of co-development manufacturing organizations (CDMOs) may likewise assist cultivated meat manufacturers by removing technical, financial, and capacity burdens.

Planning for success

Research into other aspects of the bioprocess design volition too be important. Cultivated meat manufacturers will need to be equipped with state-of-the-fine art sensor equipment, ideally integrated into the bioreactors themselves. Companies will also need to develop processes that are amenable to automation and real-time responses. These processes should integrate medium recycling and waste stream valorization to maximize their efficiencies.

The differentiation, maturation, and harvesting of cells for cultivated meat is likely to require unique innovations and bioreactor designs that address specific challenges for each of these phases. Success in these areas may be bolstered by interdisciplinary groups of biologists and engineers that have admission to research centers equipped with pilot-calibration capabilities that tin can serve as a testing ground for new technologies.

These research centers may exist sponsored by collaborations between academic and biotechnology industry stakeholders (such every bit Planet B.io in The Netherlands and partnerships betwixt The Technion, The Kitchen Hub food tech incubator, and Aleph Farms in Israel) or come from governmental grants.

The Singaporean government has moved quickly to build a burgeoning ecosystem, with millions invested into cultivated meat projects and industry incentives. In the U.s.a., the National Scientific discipline Foundation's award to researchers at UC Davis will lay the foundation for a cultivated meat research center on campus over the side by side five years.

Farther buy-in from governments around the world will be crucial for accelerating the commercialization of cultivated meat.

What's next for bioprocess design?

All hands on deck

The size and growth of the cultivated meat industry beyond the adjacent decade volition exist largely determined past the implementation of innovative bioprocess designs that form the basis of facility blueprint and their functioning. Producing volumes that capture but one percent of the global meat market volition require extensive new infrastructure that can exist supported by governments, multinational corporations, meat and life science industry incumbents, and a diverse and interdisciplinary workforce.

A maximized positive impact on the planet will also depend on future facilities beingness co-located near renewable energy sources. Other important aspects include easy access to raw materials, job opportunities that are equitable beyond rural and urban economies, and product access that is non limited to wealthy nations.

Check out additional reading and resources

Discover papers, GFI resources, ongoing research projects, and research opportunities related to bioprocess design.

- Featured project

- GFI resources

- Current research

- Research opportunities

The Cultivated Meat Modeling Consortium (CMMC)

Founded by GFI granteeDr. Simon Kahan, the CMMC is an international and interdisciplinary coalition working to advance cultivated meat through computational modeling.

Analyzing prison cell civilization medium costs

This white paper explains different routes to lowering the cost of cell culture medium and making cultivated meat economically viable.

GFI-funded enquiry projects

Learn about ongoing research by GFI grantees to accelerate advances in bioprocess pattern for cultivated meat.

Research opportunities

Explore research opportunities in bioprocess blueprint from our Advancing Solutions for Culling Proteins database.

-

Cultivated

Incorporating omega-3s into cultivated seafood

Cultivated seafood will need to exist supplemented with long-chain omega-iii polyunsaturated fat acids to be nutritionally equivalent or superior to conventional seafood. However, how these compounds can best be incorporated…

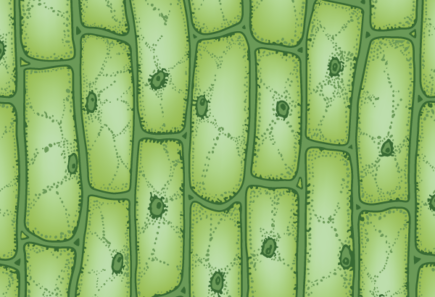

Scaffolding

Scaffolding provides structural support for cells to adhere, differentiate, and mature, making it crucial for the creation of structured meat products similar steak. More enquiry is needed to uncover the best materials and methods for amalgam unlike types of cultivated meat products.

The electric current state of scaffolds

What do scaffolds do?

The development of scaffolds for cultivated meat requires expertise in cell biology and tissue engineering with a focus on the office of the extracellular matrix. Tissue engineers aim to recapitulate in vivo tissue growth exterior of the trunk for both biomedical applications and cultivated meat.

To do and then, scaffolds must provide access to oxygen and nutrients and have textile properties (e.g., mechanical, biochemical) that are uniform with the cells housed within it. Scaffolds, together with the jail cell civilization medium, can dictate how prison cell populations grow and differentiate. In some instances, scaffolds are used every bit microcarriers to assistance the proliferation of anchorage-dependent cells in suspension bioreactors.

What backdrop practise scaffolds accept?

The nearly likely materials to be used for cultivated meat will be abundant, affordable, and food-prophylactic. Some examples include polysaccharides such every bit chitosan, alginate, or cellulose; proteins such equally zein; or complex composites such every bit lignin or textured vegetable protein.

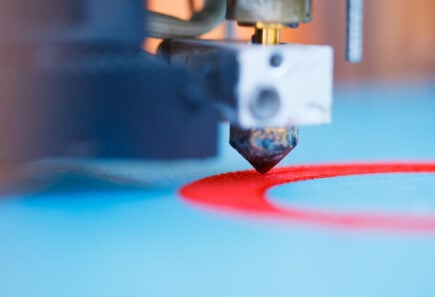

The materials can be assembled by existing techniques including 3D printing, polymer spinning technologies such as electrospinning, decellularization, tunable hydrogels, or even past nature itself (due east.grand., fungal mycelium). Several B2B companies, distinguished by their selection of textile or method of assembly, aim to supply the manufacture with scaffolds. Many others are likely to exist founded.

The option of a scaffold and its backdrop volition be highly dependent on the last product, with the scaffold having an increasingly important role in more structured products. Scaffolds may exist intentionally designed to be biodegradable such that they are replaced with native extracellular matrix by the time a product is harvested. Alternatively, scaffolds can make upwards a significant portion of the last production, creating a hybrid product.

Scaffold materials that end up in a terminal product must meet requirements for how that production may be cooked and prepared, as well as how the textile influences the product's safe, digestibility, sense of taste, and diet. Public databases of biomaterials and their properties can inform the selection of the well-nigh promising scaffold materials and methods to construct them.

Scaffold challenges

Structured products nowadays numerous challenges.

The production of thick tissues remains challenging considering all cells must prevarication within a brusque distance to nutrients and oxygen. There are ii approaches to this challenge: a top-downwardly approach where a prefabricated, porous scaffold becomes infused with cells, or a bottom-upwardly approach where minor, modular units of scaffolds and cells are constructed into a final shape.

Both approaches currently exist at minor scales, with more research needed to understand the limitations of scaffolding technologies. These information will inform which scaffolds may be best suited for large-scale, commercial production of structured cuts of cultivated meat.

As previously described, the large-calibration product of cultivated meat will rely on bioreactors. While microcarriers have been used extensively in other industries, understanding how different types of scaffolds may exist incorporated into suspension or perfusion bioreactors is in its infancy. Computational modeling may aid in the selection of a scaffold's material, shape, or topography, given certain fluid flows in different bioreactor models. Techniques to harvest scaffolds without damaging the cells or tissues will likewise be important.

Creative solutions are needed.

Other methods may apply biomaterials to house cells in 3D microenvironments, providing them structural back up simply assuasive cocky-system principles to govern their behavior within the textile. These 3D microenvironments can be formed equally spheres, tubes, or other shapes tailored to jail cell type, placed in bioreactors where they may take specific advantages (e.g., protection from shear stress), and constructed into complex shapes using bottom-up approaches. Similar outside-the-box strategies can contribute to our understanding of structured production creation.

What's side by side for scaffolds?

Maximizing potential

The holy grail of the cultivated meat industry is to produce a circuitous meat product such as a steak or chicken chest in a pre-programmed manner, each and every time. However, electric current technologies cannot yet accomplish this feat. Significant advances in tissue engineering techniques will be needed to commercialize structured products at scale. Additional challenges lie in discovering the methods and materials that will exist well-nigh amenable to large-scale production.

Bank check out additional reading and resource

Detect papers, GFI resources, ongoing enquiry projects, and research opportunities related to cultivated meat scaffolds.

- Featured newspaper

- GFI resource

- Electric current research

- Inquiry opportunities

Featured paper

Read Dr. Marker Mail service'southward newspaper "Scientific, sustainability and regulatory challenges of cultured meat" published in Nature Food.

Explore the cultivated meat enquiry tools database

This crowdsourced database compiles species-specific information on enquiry tools, reagents, protocols, assays, service providers, and other data to back up cultivated meat researchers in academia and industry.

GFI-funded research projects

Learn about ongoing research by GFI grantees to accelerate advances in cultivated meat scaffolds.

Research opportunities

Explore research opportunities in scaffolding from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

Incorporating omega-3s into cultivated seafood

Cultivated seafood will need to exist supplemented with long-chain omega-3 polyunsaturated fatty acids to be nutritionally equivalent or superior to conventional seafood. Nevertheless, how these compounds tin can best be incorporated…

Stop product considerations

Some cultivated meat prototypes have been gustatory modality-tested but many sensory characteristics are unknown. Cognition from meat science and food scientists tin can help create the full range of cultivated meat products that compete with or outperform their conventional counterparts on gustatory modality, quality, and nutrition.

The current country of end products

What might the commencement generation of cultivated meat products look like?

Many tasty, compelling cultivated meat prototypes have been created, including shrimp dumplings, pork sausages, chicken nuggets, beef steak strips, fish maw, foie gras, and salmon nigiri, to name a few. But cardinal questions remain concerning what the outset canonical products will expect like. Volition they be structured or unstructured? What are their costs? And how will they exist regulated?

The first generation of canonical products may look quite different from company to company, but it'south likely we can predict some characteristics. From a technical standpoint, the creation of unstructured, minced product types are easier to create, thus this grade is likely to represent the beginning generation of products on the market. Every bit previously mentioned, fully structured products will exist dependent on advances in scaffold technologies and are likely to go far on the market subsequently.

Similarly, the costs of first generation products volition come at a premium. Ane way to offset these costs is by creating a hybrid product where cultivated animal cells are combined with establish-based ingredients. The percentages of each may vary depending on the product's price, blazon, and sense of taste profile. Some companies aim to sell cultivated animal fats as ingredients, while others may choose to focus on cultivated muscle tissues.

To be granted regulatory approval and be labeled as a meat product, cultivated meat must accept similar nutritional profiles as their conventional counterparts. The nutritional data volition take to exist collected by companies and submitted to regulatory authorities prior to approving. To date, the nutritional data of prototypes remains privately held every bit companies continue to iterate on their first products. Sensory and nutritional data could be published in open-access journals to increase the transparency of the industry.

Terminate product challenges

Competing on all aspects of meat quality

Replicating all of the features of conventional animal meat using cultivated meat processes is probable to be challenging. For example, proteins and metabolites that give meat products their colour, smell, and cooking properties may be expressed differently in cultivated meats.

Additionally, it is unknown whether the mail-mortem enzymatic events that can influence meat texture occur similarly in cultivated meat products. Added ingredients that aid in the color, binding, and texture of cultivated meat may be needed, as featured in establish-based meats.

To discover the extent to which at that place are differences, meat scientists are needed to decide the backdrop of cultivated meat products. Additionally, food scientists will need to assist in formulating the best products across a range of versatile dishes. Research teams in academia that incorporate kinesthesia from biology departments together with meat and food science departments can accelerate progress in these areas.

What's next for end products?

The time to come is bright.

Companies have a large toolset available to continue improving upon cease-product characteristics. Improvements in nutrition may be possible past tailoring jail cell culture media ingredients for desired outcomes, such as increased omega-3 fatty acids or higher vitamin and mineral content.

Genetic applied science, if permissible, could be used to remove allergens or proteins linked to cancer run a risk in certain forms of meat. Information technology could likewise insert genes that can fortify products with vitamin A precursors not found in conventional meats, or create personalized nutrition for specific populations.

Consumer research indicates that a majority of consumers are willing to endeavour cultivated meat or even pay a premium. Willingness to endeavor is highly correlated to the amount of data given to consumers almost the cultivated meat production process and its benefits compared to conventional meats. Resources with accessible, educational information about cultivated meat, together with industry transparency, will be crucial for the adoption of the technology.

The Craven, a test-kitchen and eating house in Israel founded by SuperMeat in 2020 is intended to permit consumers to dine on cultivated craven dishes made under the same roof. Novel dining experiences and new culinary creations promise to lure in new consumers and redefine how nosotros view our human relationship with meat products. Cultivated meat promises to exist an ever-evolving manufacture for decades to come!

Check out boosted reading and resource

Notice papers, GFI resources, ongoing research projects, and research opportunities related to stop-production formulation.

- Featured newspaper

- GFI resources

- Current inquiry

- Research opportunities

Featured paper

Read "Sensorial and Nutritional Aspects of Cultured Meat in Comparing to Traditional Meat: Much to Be Inferred" in Frontiers in Diet.

GFI resource

Dig into open-access resources created past our experts.

GFI-funded research projects

Acquire about ongoing enquiry by GFI grantees to accelerate stop-product conception for cultivated meat.

Research opportunities

Explore research opportunities in end-product formulation from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

Incorporating omega-3s into cultivated seafood

Cultivated seafood will need to be supplemented with long-chain omega-3 polyunsaturated fatty acids to be nutritionally equivalent or superior to conventional seafood. However, how these compounds can all-time be incorporated…

Come across the authors

Elliot Swartz, Ph.D.

LEAD SCIENTIST, CULTIVATED MEAT

Elliot Swartz analyzes scientific progress and bottlenecks in cultivated meat.

Areas of expertise: stem cell biology, neuroscience, cultivated meat.

Claire Bomkamp, Ph.D.

SENIOR SCIENTIST, CULTIVATED MEAT & SEAFOOD

Claire Bomkamp is focused on cultivated seafood and driving forward GFI's Sustainable Seafood Initiative.

Areas of expertise: the science and technology of cultivated seafood, cultivated seafood startups, research, and university programs, scaffolding, scientific discipline advice, fish puns.

williamsmishe1945.blogspot.com

Source: https://gfi.org/science/the-science-of-cultivated-meat/

Belum ada Komentar untuk "Trout Scientific Illustration Beef Cow Scientific Illustration"

Posting Komentar